- Description

-

Product Description

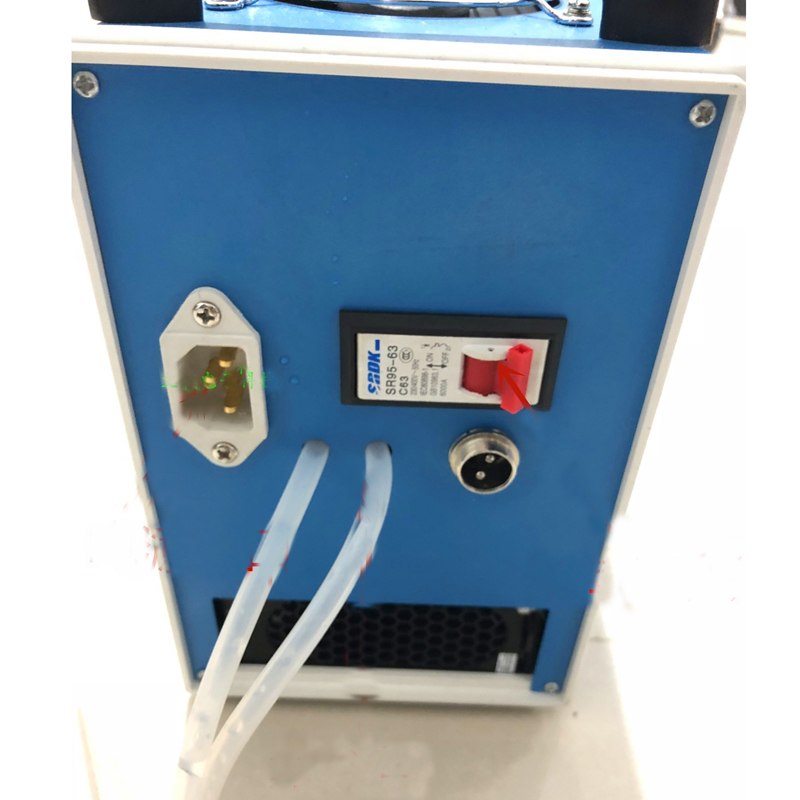

Induction Furnace Metal Smelter

Induction furnace metal smelting is a small AC110V-220V power induction heating machine used for heating small iron materials. This machine can easily dissolve gold, silver, copper, metal, aluminum, and iron. You can use a 70mL graphite crucible to reach the maximum 1600 degrees Celsius. Its dimension is 380 x 140 x 210. Its maximum DC operating current is 50A with direct heating of metal iron up to 800-900 degrees Celsius. It has a heating ring size with a size of 70 x 60 x 73 (inner diameter x outer diameter x high).

Induction Furnace Features

It has large LCD screen display systems that expose the parameters. It includes current, voltage, motherboard temperature, etc. You can easily switch the language from Chinese to English and vice versa. This product has an overload protection switch as well. It can control the current just in case it suddenly overloads. It also has high-power fans. These fans are responsible for heat dissipation. Aside from that, it has an internal water cooling circulation feature. It is to prevent the overheating of the heating coil. Plus, it is integrated with a power supply to avoid complicated wiring. It has a heating ring with high-temperature insulation material to prevent a short circuit when using the heater. The heating ring is easy to remove and customize as well.

Safety Measures In Using Metal Induction Furnace

You should follow the booth sequence during the first turn of the main power switch. Then, wait for a few seconds and check if the fan and pump are working. Afterward, check for the voltage display on the screen. Wait, until it reaches the 48V. After that, start turning on the inductive heating switch. If not in use, make sure to turn off the heating switch first. Then, followed by the power supply switch. So, the cooling system will cool down the machine system. Lastly, pay attention to the parameter’s changes. Especially, the current, voltage and the motherboard’s temperature.

WRITE YOUR OWN REVIEW